Zigzag printing MY—type zigzag gin

The 6MY98-17 brush-type sawtooth gin is suitable for sorting cotton with a fiber length of 23~33mm, a moisture content of no more than 10%, and preliminary cleaning. This equipment can effectively remove special, heavy and stiff cotton, cotton leaves, infertile particles, dust and other small impurities in the cotton. It can improve the appearance and color of the cotton, improve the quality of the cotton, and ensure the lint. Improve the quality of finishing and improve the efficiency of the cotton gin.

(1) Structure of cotton gin

6MY98-17 sawtooth gin is composed of blower and flower feeding, ginning part, transmission system and other parts, as shown in Figure 8-6.

Among them, the blowroom and flower feeding part is a cleaning type blowroom and flower feeding machine, which consists of three parts: cotton feeding, cleaning, and noil recovery. The ginning part consists of three parts: the front box, the middle box, and the back box.

1. Blowing and feeding part

The function of the blowing and feeding part is to further loosen the cotton and remove impurities in the cotton; second, to adjust the feeding amount of cotton according to the needs of ginning. Continuously and evenly feed the cotton to the ginning section.

The cleaning and flower feeding part is divided into three parts: cotton feeding, cleaning and recycling.

(1) Structure of cotton feeding part: The main components of this part are a pair of pattern feeding rollers and speed regulating device, opening roller and impurity discharge net. The two flower feeding rollers have the same specifications. When one roller rotates, it is driven by a pair of gears with the same number of teeth, and the other roller rotates at the same speed.

The seed cotton enters the gin from the entrance on the upper part of the flower feeding roller. The flower feeding and opening roller is a spike roller. An impurity discharge net is installed on the outer periphery of the opening roller. The impurity discharge net is made of punched steel plates and adopts a long shape. The holes are staggered.

(2) Structure of the purification part: The main components of this part include a sawtooth roller, a stiffening grid, a wire brush, and a small brush roller.

The diameter of the sawtooth roller is 350mm and the rotation speed is 437r/min; the grid is composed of a precision dialing tube with a diameter of 20mm, side plates and reinforcing ribs; the function of the small brush roller is to move the sawtooth roller and the recovery sawtooth roller together The sub-cotton brush falls down and supplies the ginning part.

(3) The structure of the recycling part: This part consists of a recycling sawtooth roller, a wire brush, an impurity removal grid, a small brush roller, an impurity removal spiral, etc. The structure of the recycling sawtooth roller is the same as that of the sawtooth roller, and its function is to recover single particles of cotton discharged from the rigid grid. The impurity removal spiral is left-handed and rotates at 110r/min. Its function is to timely export the stiff cotton, bell shells and dust discharged from the blow cleaning and flower feeding part to the outside of the machine.

2. The embossed part

The embossed part consists of three parts: the front box, the middle box and the back box.

(1) Structure of the front box: The left and right side walls of the front box are welded by steel plates. The main components include cotton pick-up rollers, shell rib rows, and deflectors.

The licker-in roller is made by hooping a log roller on a shaft with a diameter of 30mm, wrapping it with a thin steel plate, and then installing several rows of spikes on the surface in an inclined shape. The diameter of the licker-in roller is 120mm, and the rotation speed is 314r/min. A steel plate punching net is installed under the cotton-picking roller. Its function is to recover the small flower heads that fall from between the cotton-picking roller and the saw blade roller to reduce clothing losses. A brake wheel is installed on the right end of the cotton-picking roller. When the working box is opened, the brake belt and the brake wheel rub, causing the cotton-picking roller to stop rotating.

The rib row of the resistance shell is composed of 97 shell resistance ribs and 2 side resistance shell ribs

fixed on the angle steel. The position of the rib row of the resistance shell can be adjusted by loosening the fixing bolts on both sides and adjusting the jack screw to make the rib row of the resistance shell swing back and forth.

The guide plate is an inclined steel plate located in the front box. Its function is to guide the cotton entering the front box to the cotton picking roller.

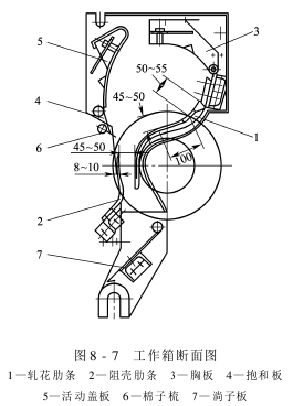

(2) The structure of the middle box (work box): The main components of the middle box include embossed rib rows, chest plate, movable cover plate, holding plate, saw blade roller, cotton comb and work box adjustment mechanism, work box The box opening and closing mechanism is shown in Figure 8-7. The embossed rib row is composed of 97 embossed ribs and 2 side ribs mounted on one beam. The embossed ribs are cast from cast iron and the surface is galvanized.

Saw blade The drum consists of 98 saw blades and 96 aluminum spacers, which are alternately sleeved on a shaft with a diameter of 74.6mm, and both ends are fixed with clamping washers and nuts. Both ends of the saw blade drum are fixed on the frame with square outer spherical bearings with eccentric sleeves.

The chest plate, movable cover plate and hugging plate are all curved and made of 1.5mm thick stainless steel plate. The curvature radius of the chest plate is small, followed by the movable cover plate, and the hugging plate is larger. The two side walls of the middle box are lined with stainless steel plates to reduce the resistance of the cotton roll.

The cotton comb is of plate type, its shaft is installed on the wall panel, and the right end extends out of the wall panel and is connected to the adjustment handle to adjust the inclination angle of the cotton comb. The cotton comb can move forward and backward to cooperate with the work of other machine parts.

(3) Structure of the rear box: The rear box is mainly composed of brush roller, upper row of debris knives, lower row of debris mechanism, rear windshield and other components.

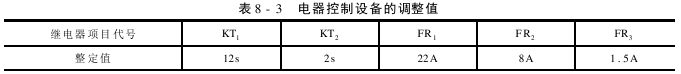

The axis line of the brush roller is lower than the axis line of the saw blade roller and is installed behind the saw blade roller. The brush roller is made of 5 aluminum discs fixed on a shaft with a diameter of 75mm. The discs are tightly wrapped into a cylinder with galvanized steel plates, and 24″ are fixed on the surface of the roller with pressure plate screws.� phenomenon, the setting values of KT (time relay) and FR (thermal relay) should also be adjusted according to Table 8-3.

The above work After completion, you can follow the steps below to perform power-on debugging.

(1) Turn the toggle switch SA2 in the control cabinet to the trial production status position.

(2) Close the air switch on the right side of the control cabinet. At this time, the power indicator light on the control cabinet lights up and the voltage indicator indicates the power supply voltage value.

(3) Turn on the key switch and the indicator light on the button box will light up, indicating that the control circuit is connected.

(4) Press the start button of the main motor/blowroom motor of the gin machine to start the motor.

(5) Press the box closing button, the working box motor will rotate forward, and the working box will close to the working position.

(6) Turn the three-position button SA3 to the manual or automatic position, manually rotate the potentiometer RP, and the flower feeding roller will run at the set speed.

(7) Press the unboxing button, the working box motor reverses, the working box leaves the working position, and the flower feeding roller stops rotating.

(8) Turn SA2 to the working position, and turn the three-position button to the stop position.

At this point, the adjustment of the electrical control system is completed. It should be noted that the two travel switches on the box opening mechanism should be adjusted so that the gin machine can open and close the box accurately. If there is any abnormality, press the emergency stop button immediately to prevent accidents.

4. Use and maintenance

To operate this machine, you must hold the machine key. If the system has been debugged, move the SA2 in the cabinet to the working position and start it in the following sequence:

Main motor → Blowing motor → Box closing → Flower feeding motor

The parking sequence is the opposite.

If an emergency occurs at work, the emergency stop button should be pressed immediately to prevent an accident.

Electrical equipment should be kept dry and clean, free from vibration and collision, the control cabinet should be cleaned regularly, and wiring, electrical components, and motors should be regularly inspected and maintained.

AAADFGTEHTRY